Surface grinding

The

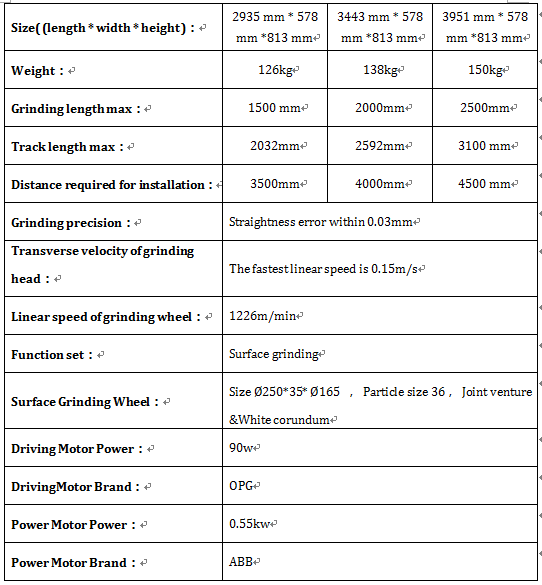

steel needle whose angle on the elastic card clothes changes are processed by surface

grinding technology to make the whole card cloth flat and the blade angle of

the steel needle are consistent.

The

actual operation as shown in the figure:The

grinding head conducts transverse reciprocating motion. A flat grinding wheel

is installed on the grinding head. The grinding wheel is rotated at high speed

and the steel needle on the elastic card cloth are grinded so as to realize the

technological requirements of the overall grinding of the steel needle.

The

product structure is mainly composed of four parts: (1) Grinding head assembly,

(2) Guide rail assembly, (3) Bracket assembly, (4) Electrical control box.

1. The

grinding precision of the product is within 0.03mm, comparable to imported

products.

2. The

electronic control and mechanical parts of the product are integrated, with

high integrity and easy to

install.

3. The

product is light and use a lot of aluminum material, running light.

4. Low

maintenance cost without refueling when the product is running.

5. The

grinding precision and linear speed of the product are controlled by button, and

the operation is

simple.

6. The

track is made of high quality alloy steel, which is not easy to deform after

quenching�����。

7. The

product quality is stable, and the after-sales service is perfect, so that

customers have no worries.

8. Wide

range of products can meet the needs of most customers.

Service :400-616-3535

Service :400-616-3535

Tel: +86 512 63365510

Tel: +86 512 63365510

Fax:+86 512 63341238

Fax:+86 512 63341238

Wechat:szylfg_public

Wechat:szylfg_public

Add:No.9, East KaiFa Rd, Wanping Community, Taihu New Town, Wujiang District, Suzhou, China

Add:No.9, East KaiFa Rd, Wanping Community, Taihu New Town, Wujiang District, Suzhou, China