Mule spinning elf platform is one of You Lian e+ series products, it is an internet based intelligent platform of monitoring and management on mule spinning machine, it works by install an intelligent gateway system on the mule spinning machine, and upload all kinds of data (mainly obtained from the sensor) from the device to the cloud server, though data processing, authorized members can get real-time information from PC and App terminal to monitor and manage the device, and fully comprehend the machine’s usage parameters, production, operation, failure and so on.

Enterprise managers can’t see the status of equipment in real time.

High cost of after-sale maintenance and low efficiency.

Equipment failure code can’t be uploaded in time, which increases maintenance difficulty and time.

The equipment does not have the function of independent diagnosis and investigation, which affects the maintenance efficiency.

Easy to cause unplanned shutdown without early warning device.

1.Intelligent monitoring and management platform based on Internet Plus, Internet of Things and Big Data research.2.Remote after-sale service to improve maintenance efficiency and reduce maintenance cost.3.To realize remote system upgrade and data update and other services.4.Breaking the traditional mode of information exchange, the data chain of whole production becomes visible.5.Early warning of faults to reduce unplanned shutdown.6.Fault alarm, quick diagnosis. Inform the cause of the failure and solution.7.Customizable data interface and integrate with customer’s management system..

The real-time data chain is built on the internet, which terminates the past data fragment mode of interaction. Whole production data chain of the process becomes visible, and the client can master parameters, production operation, failure maintenance and so on of the current device by PC and App.

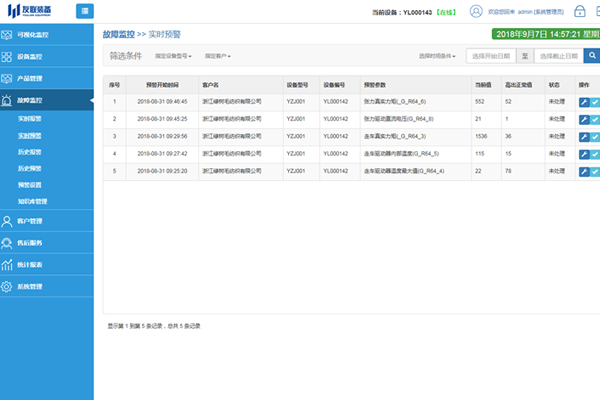

The monitoring and management platform can percept the upcoming failure including the failure characteristics of location, time and possible cause by fault early warning signals. Instead of repair, planned maintenance reduces the shutdown time at most.

The system can push the relevant fault data to the App or PC of the related authorized personnel. The personnel can totally understand the true cause of the failure and current status of the device, which reduces the time to solve the problem.

Through platform, the database of equipment operation status is established: equipment failure and solution will be recorded in the knowledge base.

Service :400-616-3535

Service :400-616-3535

Tel: +86 512 63365510

Tel: +86 512 63365510

Fax:+86 512 63341238

Fax:+86 512 63341238

Mail: Info@ylfj.com.cn

Mail: Info@ylfj.com.cn

Wechat:szylfg_public

Wechat:szylfg_public

Add:No.9, East KaiFa Rd, Wanping Community, Taihu New Town, Wujiang District, Suzhou, China

Add:No.9, East KaiFa Rd, Wanping Community, Taihu New Town, Wujiang District, Suzhou, China

Sweep, Follow Us

Sweep, Follow Us